Ray Palmer has had a go at various riding disciplines. Since retirement, he has acquired a collection of 50cc race bikes, but the Pope Special, for close personal reasons, is a particular favourite. Alan Turner tells the story.

Words: Alan Turner Photographs: Alan Turner and Ray Palmer Collection

Nowadays, the sport of 50cc racing is a minority interest, but it wasn’t always so. In the Sixties, the egg-cup class featured in most race programmes.

There was a keenly contested ACU Championship and the FIM awarded it World Championship status in 1962. Hugh Anderson secured both titles during the Sixties with the benefit of a works Suzuki. The smaller classes were enormously important to the Japanese manufacturers.

In Britain, the class offered racing about as close to affordable as it could get. If the rider was of jockey weight, then it was quite possible to be a front-runner.

At first, the Japanese factories kept their high performance machines to themselves and European machines filled the grids.

There were a few exceptions, such as brothers Dave and Mike Simmonds who rode bikes from Tohatsu after their father brokered a deal with the Japanese manufacturer. His travels to the Orient as an airline pilot working for BOAC (a predecessor of British Airways) enabled him to make the necessary contacts.

For a couple of seasons, the leading lights in 50cc racing were subjected to a fairly constant irritant – Alan Dawson, riding the Pope Special.

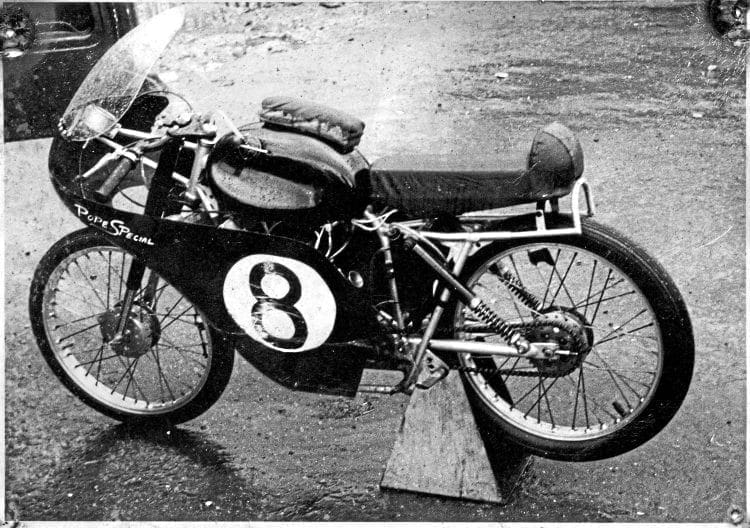

This bike was a regular fixture at Brands Hatch meetings and frequently tested there as it was developed in a modest workshop not far from the Kent circuit.

The first Pope Special was a Demm 49cc ‘Dik Dik’ two-stroke sports bike. It was a second-hand purchase by John Pope and his brother Tony and offered performance on a par with anything else available over the counter at the time.

Demm, an Italian company, also produced some impressive four-stroke overhead cam models, but these were rare and unaffordable. With two-stroke exhaust technology still in its infancy, the Dik Dik came equipped for racing with a short megaphone exhaust; it was standard wear for such machinery.

Alan Dawson had already raced the bike for its previous owner and his riding services were taken up once more.

Team Bonding

In the early days, Ray Palmer was involved as a test rider. Like many aspiring tuners, he had spent hours studying Phil Irving’s ‘Tuning for Speed’. After applying this perceived knowledge and combining it with some exuberant riding on his BSA 250 C12 road bike the engine suffered a snapped con-rod, the sheared end of which protruded from the bike’s crankcase.

As an impecunious trainee, it looked like the end of motorcycling for a while – until he was introduced to John Pope. John worked for well-known dealers and former racers Schweiso Brothers, with premises at Dartford in Kent. John brought a broad range of engineering skills he had learned with previous employers.

As Ray could not afford pukka labour rates, John agreed to repair the bike for him as a moonlight job. Ray was impressed with the skills involved, which even extended to gas-welding repairs to the aluminium crankcases.

Above all, Ray’s ambition was to get involved with racing motorcycles, but his finances fell far short of his ambitions. Nevertheless, he was so keen that he gave up a steady five-day week job to work for Mence Smith (a chain store selling household goods). In common with many retail businesses then, Mence Smith closed early on Wednesdays.

This enabled Ray to get to Brands Hatch for the open practice that took place on that day almost every week. The precursor of track days, riders simply turned up and, provided they had basic riding kit and the modest track fee, they were allowed free run of the circuit in a series of 20-minute sessions.

Soon, Ray was a development rider on the Pope Special. Alan Dawson was busy as a welder/fabricator on lucrative civil engineering work. On Wednesdays, while Alan earned money, Ray was lapping Brands Hatch, evaluating the latest changes John had made to the bike.

If Ray’s times improved, then it was more or less given that Alan would also improve his times in racing conditions. Soon both rider and bike were becoming more effective, and Alan was starting races closer to the front of the grid.

At seven stones, Alan Dawson was a competitively sized rider. It was John Pope’s mission to provide him with a more competitive bike.

Development started modestly with basic preparation to standard specification. An early lesson was learned after a Snetterton retirement following a con-rod fracture.

At one race meeting, the works entries from Motom frightened everyone with their superior speed, until they all retired.

The eventual victor was riding an Itom prepared by Chisholm Brothers, agricultural engineers from Maidstone, Kent. John recalls noticing the cylinder of the leading bike was glowing dull red towards the end of the race, which led to the thought that water-cooling would be an aid to consistency and reliability.

Upping the pace

The nights got busier in John Pope’s shed, where all the work took place – drawing, machining, fabrication and assembly. Alan Dawson, Ray Palmer and Bob White were often there until the small hours of the morning.

There were other jobs for other people. Short circuit ace, and Schweiso work colleague, Syd Mizen would call and get John to help prepare his bikes, with machining jobs such as facing new brake linings.

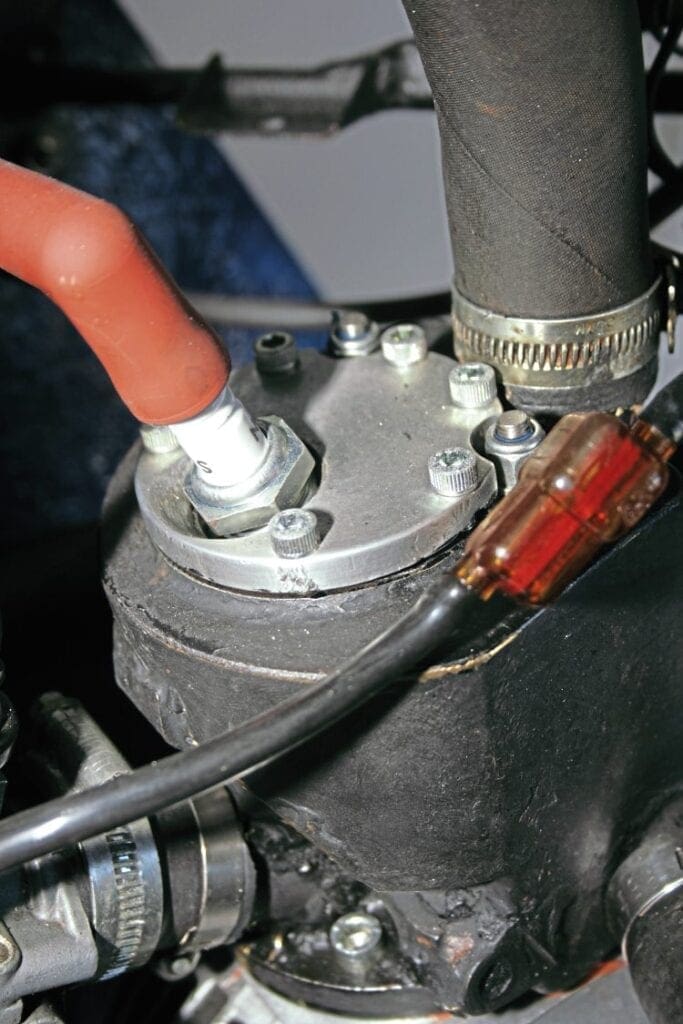

Rather than compromise the standard air-cooled Demm cylinder, a new one was fabricated from a combination of tube, plate and sheet steel.

After the ports were filed into the barrel, it was bronze-welded together and the bore and gasket faces finish-machined. Water was directed to the area round the exhaust port and returned from the cylinder head to the radiator (half an LE Velocette unit) by thermo-siphon.

The now surplus air-cooled Demm cylinder and Dell’Orto carburettor were fitted to an NSU Quickly moped that Tony Pope used for commuting. With the standard Quickly exhaust and the two-speed gearbox, Tony still managed to get stopped for speeding on his way to work! As the policeman could not believe what he was seeing, Tony was let go with a caution.

Taking advantage of the improved thermal stability conferred by water-cooling, the ports were widened, but the timings remained the same as those proven to work by Demm. John recalls the increase in inlet port size encouraged them to find a bigger carburettor; an Amal of around one-inch bore.

To reduce churning losses with an oil-bath transmission, the gearbox lubrication was changed for an oil spray with an external tank. An oil pump from a Tiger Cub was driven by the final drive sprocket and the supply side sprayed oil over the gears, while the scavenge side picked up from the bottom of the gearbox and returned the oil to the tank.

Unfortunately, if the bike was standing still with the engine running, the gears received no lubrication. It was sometimes necessary to lift the back wheel and make it revolve if the bike was held on a starting grid for too long.

The bike also acquired a fairing. Its addition gave John serious misgivings, although testing proved otherwise. Still fitted with the megaphone exhaust, Alan had not allowed for the surprise gain in speed and took a tumble at Clearways at Brands Hatch.

Alan Dawson recalls riding the bike as ‘a novel experience’. Tucked away down the main straight at Brands Hatch, the bike was relatively slow, but he could carry plenty of corner speed and in open practice sessions would often overtake Manx Nortons on the way round Paddock Hill Bend!

At one memorable race meeting, the dry 50cc race was faster than the later, wet 350 race – a feat that merited headlines in the weekly motorcycle press.

The Demm’s downfall was the gearbox mainshaft. This broke at a Castle Combe race. With little hope of securing a replacement, it was the Simmonds brothers’ father who came to the rescue. On a BOAC flight to Milan, he managed to source a replacement.

Next Itom

Eventually, with no realistic long-term solution, it was decided to abandon the Demm engine and find a new way forward with an Itom engine. A standard model was located. There was no spark and John, by feigning mechanical ignorance, secured the bike at an extremely reasonable price. John was impressed with Itom build quality. T

he moped engine used the same robust bottom end as the Itom sports bikes; the only difference was the barrel and piston.

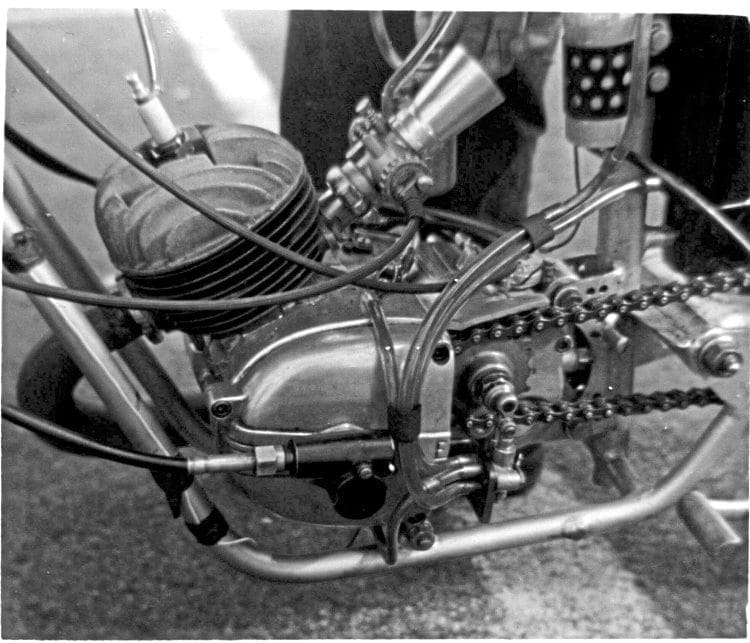

The engine was fitted into the Demm frame. As Bob White, who also rode the bike, was taller than Alan, the opportunity was taken to extend the frame by four inches. The forks are ‘upside down’ style and the tank had a neat Monza filler, angled at 90 degrees.

John also developed a method for big-end assembly. One of the shed visitors, John Tompkins, worked for Verdict, a company specialising in measuring equipment, and he provided a suitable gauge for John to grade the 1/4×3/16in rollers used in the crowded row big-end bearing to extremely close tolerances.

This system worked very well and enabled him to create an optimum assembly. The engine was topped with a new cylinder, using the same system of water-cooling. An Itom race kit piston incorporated profiles for the inlet and transfer passages. Sparks were courtesy of a 10mm plug in a machined squish cavity. The Amal carburettor and Demm exhaust were used again.

The pumped gearbox lubrication system used on the Demm appeared to be of minimal benefit, so it was not used. Instead, the gears ran in special, low-viscosity transmission oil. A positive stop, foot-change mechanism replaced the scooter-style twist-grip change. There was a battery powered ignition system, using a high output coil.

Next stage was to use the Demm megaphone as the start of a full resonant exhaust system. A large diameter tube was welded to it, with an adjustable exit.

Calculations by John’s brother Charles were combined with track testing. Charles used a slide rule to establish what appeared to be an optimum system. The bike was certainly giving more power than rival Itoms. The rear hub was modified to take a range of readily available sprockets, enabling the overall gearing to be optimised for each circuit.

There was no provision for a rev-counter. John fitted one and, after all these years, still has the fixture that enabled him to align the mounting boss before welding it to the moped engine’s outer cover.

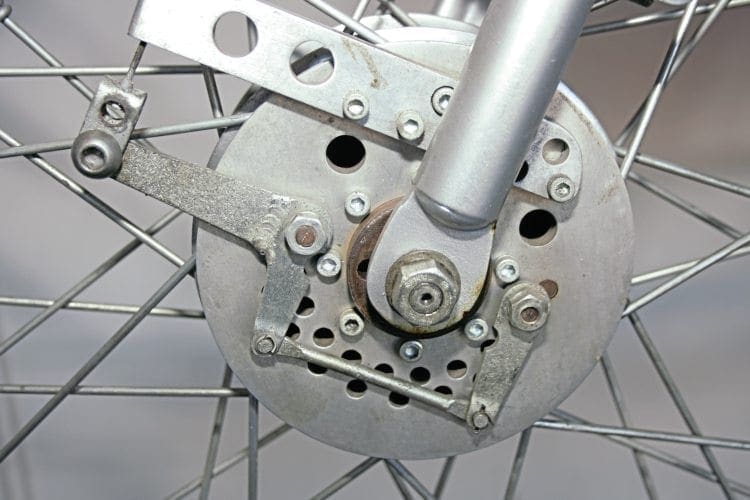

New hand levers were made and the front brake was changed to a twin-leading shoe set-up with a new back plate and wider shoes.

The new arrangement was rather savage and Ray Palmer fell off at Paddock Hill Bend after it locked up after which the brake was changed to a softer and more predictable twin-trailing shoe set-up.

Long way round

Alan recalls that although he was usually a front-runner, he could never pin down the flying Dave Simmonds. Most races at that time were over the full Grand Prix circuit at Brands and the 2.65-mile lap length rather extended the bikes.

“One race, on the last lap, we were at Stirling’s when Dave missed a gear, the engine dropped right off the pipe and he even waved me past, I should have got the win, but we were lapping back markers on the way round Clearways to the flag. I got baulked and Dave came past me. I never won at Brands on the Pope Special, but I got a lot of second places.”

John recalls the bike as being very easy to start, and mainly trouble free, except for the occasional whiskered plug. He recalls a Snetterton race when Alan pursued Dave Simmonds down the main straight in pouring rain, they had pulled out a huge lead over the rest of the field–then the Pope’s spark went out.

The bike enjoyed some success at a Cadwell Park International. Hugh Anderson, on the works Suzuki, got a poor start, while Alan got a scorcher. Eventually, the three-speed ‘box on the undulating Cadwell course was just too much of a handicap. Anderson came past and so did Dave Simmonds, but third place was still a tremendous effort.

Island of Dreams

Then there was the Isle of Man TT, which was another rather wild ambition. For this, John had thinned the clutch plates, to get a further two into the pack. A reworked exhaust should have provided more power.

However, the punishment of the Mountain circuit resulted in a broken weld to an exhaust mount, when Alan was in about seventh place, among the privateers. The only consolation was when they were spectating at the soaking 350 race to watch their friend Syd Mizen score a fine third on an AJS 7R.

Next stage in development was another cylinder; this one had a rear-facing exhaust port. A standard Itom piston was used as experiments were made with the combustion chamber. This part of the cylinder head was deliberately ‘dry’, separate from the water circulation; so that various squish profiles could be exchanged quickly, without disturbing any other part of the engine. Further, less successful experiments involved a flat slide carburettor and a Wal Phillips-style injector.

In hindsight, John regrets not sorting out the gearbox first. “We definitely had the power, but we lost out on circuits where we could not get the gearing right.” While the Japanese works bikes were fitted with eight or nine gears, the standard, three wide ratios provided by Itom eventually proved the single biggest drawback.

“While there would have been considerable work involved in creating a two-speed, chain driven multiplier, this would have provided a six-speed transmission. Alan Dawson eventually sourced a four-speed gear cluster, but it was never fitted to the bike. As well as the lengthened frame, further chassis tuning involved fitting gas-filled shocks at the rear. What the effort lacked financially, it made up for in innovation.

“Watching a race one day, Frank Sheene asked John Pope if he would mind if Alan had a go on one of his bikes. John knew that if Alan was to further his career, then he had to move on. Alan progressed to race Derbi and Bultaco machines for Frank. Alan sums up the period philosophically: “It was a mixture of drama and success–but that’s racing.”

Bob White became the third rider of the Pope Special and he notched up further successes.

By 1964 John had no time for further development work. He was engaged to be married and he and his brother had started up in business. Their father died suddenly and long nights down the shed were incompatible with the new pressures of life.

He withdrew from the race scene and eventually moved to Lowestoft in 1972 to pursue his business interests.

As the race effort wound down it is easy to think of what might have been. John had started on a couple of other projects. Not far from his home was the busy industrial area at the side of the Thames, where there was a huge range of engineering facilities.

One of the shed regulars was a pattern maker. He provided John with castings that were to be the basis of a rotary valve single. The layout was inspired by the design of Vespa’s GS150 scooter engine.

Further in the future was the possibility of a 50cc twin, a format that was the secret of success for the Simmonds’ Tohatsu. It would have used Cyclemaster pistons, from the 32cc rather than the 25cc version, in a short stroke motor.

The project was never finished and unfortunately, the parts seem to have vanished, as has the Mk II water-cooled barrel.

Resurrection

The Pope Special was passed on, but the next owner did nothing with it and it languished in a garage for many years. Ray Palmer knew of its whereabouts and when he was in a position to devote the time to restore it, he bought it back. The aim was to prepare it for one of the well-supported Bill Ivy Memorial meetings.

Alan Dawson was looking forward to being reunited with the bike, but an ignition fault meant that he did not get an outing and a chance to relive past glories. John Pope regrets not keeping the bike but admires the efforts Ray has made in bringing it back to life.

Concessions were made in the restoration, with some modern internals to the engine. A Motoplat unit replaced the total-loss battery and coil. John Pope approves, as he points out: “These things simply weren’t available at the time we were racing.”

Ray Palmer had his swansong road race outing on the bike at the Belgian Classic TT, where he recorded a third place before hanging up his leathers for good. The bike makes occasional appearances at classic events, where Ray is happy to listen to people say: “I remember seeing that.”

John’s Legacy

As Ray became more involved in bike preparation on his own account, John’s influence was there to see. While underseat exhausts may appear to be a recent vogue, an MV grass track bike prepared in 1964 used a flattened megaphone exhaust as the rear mudguard.

Two years later, an Ariel Arrow grass track bike (still in Ray’s possession) had the exhausts as part of the rear subframe. “Everything was still being done on a shoestring,”Ray recalls. “We found a source of tubing off-cuts up in London and we could go and buy short lengths of aircraft-spec material.”

Ray eventually made a career out of repairing bikes, setting up shop as Maidstone Motoliner, where he has since been joined by his son, Tommy.

Ray on the brothers

Ray Palmer has great admiration for John Pope’s skills as an engineer. He recalls being at close quarters in episodes other than the achievements with the Demm/Itom. On one occasion, a rider approached John with the gear selection mechanism from a Greeves Silverstone.

A missed gear too often had resulted in a trip down the road and he wanted John’s opinion. John threw the parts straight into the scrap bin. He made the rider a completely new, fully functioning, selector assembly.

John’s brothers, Charlie and Tony, were involved in the race effort, although to a lesser degree. Ray had taken to riding moto-cross, on a Greeves Challenger with an earlier round barrel engine. Charlie Pope had studied two-stroke exhaust systems and came up with the dimensions for an expansion chamber.

His calculations called for a system six feet, six inches long. It looked an impossible task to lose such a thing on a race bike, but cutting and welding tucked the exhaust neatly away, wrapping it around the engine. The result was so successful that Ray even beat a works square-barrel Greeves.

“We were also using a TT carburettor and running on methanol,” Ray chuckles. Next outing, the factory machines featured a similar exhaust system!

Read more News and Features online at www.classicracer.com and in the latest issue of Classic Racer – on sale now